3D printing has already revolutionized the world of prosthetics. Now for the first time, forward thinking dental labs can offer a precision fit laser printed cobalt-chromium RPD to their clientele.

The Process

- The dental laboratory scans the model and sends a digital file of a designed framework or model via our user-friendly customer portal.

- We design the device using dental CAD software and using the digital file we receive.

- Our 3D laser printed sintering technology produces a device manufactured to unprecedented tolerances

- The device is polished as requested and shipped with a unique certificate of authenticity issued along with a 5-year warranty *.

SELECTIVE LASER MELTING TECHNOLOGY

Dental Laboratories

No plastic patterns and casting means unparalleled consistency and precision, translating into increased polisher productivity. You can now offer your patients 3D laser printed pure chrome partials, knowing exactly their makeup.

There are multiple polishing options, fully polished, pre-polished and unpolished. We offer 3D design service and one-on-one training.

Our clients use an easy file transfer via the customer portal, allowing them to have live order tracking. Available 24-hour 3D design approval.

As a B2B company we work exclusively with dental laboratories enabling them to provide durable, highest quality on the market RPDs to the dentists and their valued patients.

Patients and Dentists

Patients are ensured of the

superior comfort, fit and reliability that only a 3DRPD removable partial denture can provide.

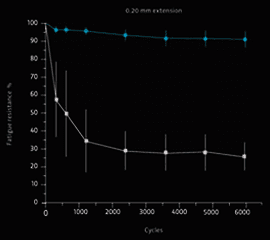

Unmatched alloy fatigue resistance removes adjustments following final insertion so no more clasps ajustments required!

Unmatched alloy fatigue resistance removes adjustments following final insertion so no more clasps ajustments required!

Dentists will be 100% satisfied with the solution 3DRPD provides, no more clasps adjustment for their patients, less chair time

Certification

3DRPD offers certification to dental laboratories eager to offer their customers the highest quality RPD technology available. Learn how you can become a 3DRPD certified lab today!

WARRANTY

Dental laboratories, dentists and their patients can rest assured as all products are shipped with a 5 year warranty and certificate of authenticity.

FDA & REGULATORY COMPLIANCE

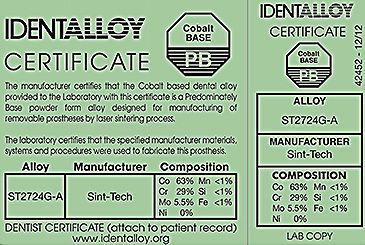

Canada regulations. Materials used in the manufacturing product are IndentAlloy® certified, attesting to adherence to the high standards set by the American Dental Association (ADA) for materials used in dental appliances.

OUR MISSION

Our mission is to provide the North American dental market with an outsourcing solution for the manufacturing of top quality laser-sintered cobalt chrome partials. 3DRPD endeavour to provide the best possible product to our customer’s, on time and at a competitive price.